~Gellan Gum Specifications

Gellan Gum Origin:

-Gellan is an anionic polysaccharide, which is produced by Sphingomonas paucimobilis bacterium(ATCC31461) through aerobic fermentation. Purified by alcohol precipitation. -In 1978, in CP Kelco Kaneko and Kang found a water soluble polymer – gellan -In 1988, Japan approved gellan gum for use in food products. -In 1992,FDA approved the use of gellan gum as an food additive. It has E-number E418.

Structure:

Gellan Gum is extremely effective at low use levels and is available in two forms.

High Acyl Gellan Gum forms soft,very elastic gels;Low Acyl Gellan Gum forms firm,brittle gels.

Features

-Forming gel ,low dosage(at lest 0.05%) forms gel-Excellent stability(PH ,Heat)-No protein interaction-Fluid gel(suspension)-High clarity-Flexibility in melting and setting temp.

Gel Formation

Dispersion

Poor dispersion will result in incomplete hydration and loss of gum functionality.

Solutions:

-Blending with dispersants such as sugar,sodium citrate etc.-Stirring or starting the agitator before adding.-Using well dispersion products such as KELCOGEL or CINOGEL GELLAN GUM

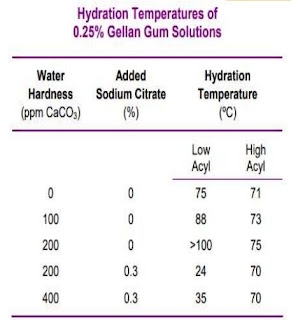

Hydration:

• Concentration of ions in solution will affect the hydration temp. such as calcium , Sodium • Low acyl gellan gum requires a temperature of 75 ℃(1670F) to fully hydrate the gum.• High acyl gellan gum hydrates between 70℃ and 80 ℃(1580F and 1760F) even in relatively high ion concentrations

Gel formation

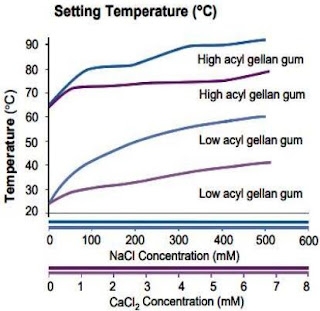

In the absence of added cations, low acyl gellan gum gels set at around 25℃ (770F), where high acyl sets at around 65℃ (1490F). With added calcium or sodium ions,the setting temperature increases.

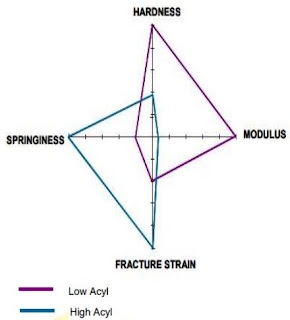

Gel Texture

• Low acyl –-hard brittle gel• High acyl—soft elastic gel• Blending two types with vary ratios a wide variety of textures can be obtained.• It is possible to obtain textures close to those of carrageenan and gelatin gels.

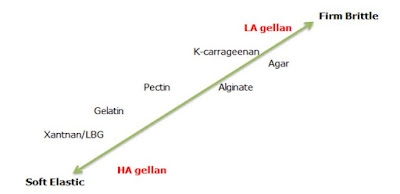

Comparation to the other hydrocolloids gel

Blends of Low Acyl and High Acyl Gellan Gum

Low acyl gellan gum gels have a firm, brittle texture. Adding a high acyl gellan gum reduces the brittleness. By varying the ratio of these two forms of gellan gum, a wide variety of textures can be obtained. Blends of low acyl and high acyl gellan gum can match the texture of other hydrocolloids. By varying the ratio of low acyl and high acyl gellan gums it is possible to obtain textures close to those of carrageenan and gelatin gels.

Blends with other Hydrocolloids

Other thickening or gelling agents, such as starch, guar gum, locust bean gum, cellulose derivatives or xanthan gum, may also be used with gellan gum in order to obtain the desired texture.

Certain hydro- colloids, when combined with low acyl gellan gum, cause a progressive reduction in the hardness and modulus values of the gellan gum gels. Brittleness remains essentially constant and springiness increases slightly.

Thermo-reversible Gels

In most practical situations, gels made with low acyl gellan gum are not thermally reversible. Most gels of low acyl gellan gum are retort or bake-stable. Gels made with high acyl gellan gum will soften with heating, and will melt with prolonged heating.

The greater the concentration of ions, the higher the melting temperature.

Milk Systems. Gels made with low concentrations of monovalent ions melt easily. For example, in milk systems both high and low acyl gellan gum form thermo-reversible gels as it is believed that in milk, gellan gum sets predominately with potassium rather than calcium ions

Degradation during Gel Preparation

Low acyl gellan gum is very stable. Like other polysaccarides, gellan gum will undergo hydrolytic degradation at high temperature, especially in acidic conditions. However, at pH 3.5, a low acyl gellan gum solution can be maintained at 80°C for up to one hour with minimal deterioration in the quality of the subsequently formed gel.

High acyl gellan gum is more susceptible to degradation so long hold times in acidic conditions should be avoided. For UHT milk process systems, the low acyl form of gellan gum should be used for long term product stability.

The Beneficial Properties of Gellan Gum Fluid Gels

Gellan gum fluid gels are solutions with a weak gel structure. They exhibit an apparent yield stress,i.e., a finite stress which must be exceeded before the system will flow. These systems are very good at suspending particulate matter since, provided the stress exerted by the action of gravity on the particles is less than the yield stress, the suspension will remain stable.

Their highly pseudoplastic flow provides extremely efficient suspension combined with low viscosity at higher rates of shear. This results in low viscosity in the mouth, making them particularly effective in beverages for suspension of fruit pulp or jelly pieces. Suspension can be achieved without adversely affecting the mouthfeel.

Other important properties of gellan gum fluid gels are the setting temperature, degree of structure and thermal stability. All of these properties are, as with normal unsheared gels, dependent upon the concentration of gellan gum and the type and concentration of gelling ions.

Fluid gel formation is employed in the production of dairy products, spreads, dressings, and sauces using scraped surface heat exchangers or during HTST/UHT processing.

Gentle agitation of a weak gellan gum gel, after it has set, is also sufficient to form a smooth, pourable fluid gel. This means that fluid gels can be formed using standard filling operations.

Last updated